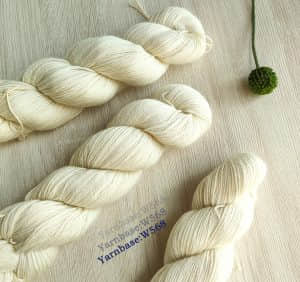

Product features:

Made from a blend of 95% superwash merino wool, 5% Nepp, it’s chunky and soft, smooth, doesn’t roll easily, and feels comfortable to the touch.

The yarn skein is 84m/150g.

The blend of NEPP gives the chunk yarn W593 a stylish effect and is suitable for hand dyeing. It is perfect chunky hand dyed yarn.

The fiber quality of the fingering yarn W291 is good and contains no other impurities, making the quality of the thread purer and more comfortable to the touch.

Product use:

The chunky yarn W593 is good choice for making hats, scarves, etc. Its soft, smooth, and less prone to rolling makes hand-knitted finished products more comfortable; while the Nepp and Lurex blend is suitable for knitting unique hand-knitted items. Whether you are a hand knitting enthusiast or a hand knitting factory, you can choose chunky yarn W593 as a raw material for hand knitting to achieve excellent results and quality.

Product maintenance:

The chunky yarn W593 is made of a merino wool blend and is a high-grade reloving yarn. To maintain the quality and effectiveness of the product, follow these recommendations when washing:

Avoid washing with too hot water to avoid shrinkage or deformation;

Please use mild detergents and avoid detergents containing bleach;

Please avoid soaking for too long to avoid damaging the fiber structure;

Please gently squeeze dry after washing to avoid strong wringing to avoid deformation or damage to the yarn;

Please avoid direct exposure to the sun when drying the yarn to avoid fading or deformation.

Production notes:

Selection of fiber materials: The fiber raw materials of fingering yarn W291 are made from a blend of merino wool, Nepp and Lurex. In the production process, it is necessary to select high-quality raw materials to avoid using raw materials that contain impurities, have short fibers, and do not meet specifications.

Production process control: Every step in the production process needs to be controlled, such as fiber mixing, spinning, dyeing, etc. Fine control of the production process can ensure the quality and effect of the product and avoid problems such as fiber fracture and color difference.

Equipment maintenance: During the production process, it is necessary to ensure the normal operation of the equipment, carry out regular equipment maintenance, and avoid production interruptions or quality problems caused by equipment aging or failure.

Strict implementation of quality inspection: In the production process, it is necessary to establish a complete quality inspection system to conduct comprehensive inspection of raw materials, semi-finished products and finished products to ensure that the quality of products meets standards and requirements.

Implementation of environmental protection measures: We need to pay attention to environmental protection issues in the production process, take reasonable environmental protection measures to reduce pollution and waste, and protect the environment and ecology.

Reasonable arrangement of production plans: In the production process, production plans need to be arranged rationally to ensure production efficiency and product quality while avoiding overproduction leading to inventory backlog and waste of resources.

Marketing strategy formulation: In the production process, it is necessary to formulate appropriate marketing strategies, including product positioning, brand building, channel expansion, etc., to enhance the popularity and competitiveness of products.

Where to search these yarnbases:

Instagram shows many yarnbases. #handdyedyarn #woolyarn #loyalyarns #indiedyedyarn #indiedyer