Core advantages:

- PREMIUM INGREDIENTS: Aran yarn W417 uses 100% super washed merino, a natural fiber with superior quality and durability. Its softness and comfort make it an ideal choice for high quality fabrics and handmade items.

- STRENGTH AND DURABILITY: Our aran yarn W417 has excellent strength and durability and can withstand frequent use and washing without loss of quality. This makes it ideal for making durable home textiles, knitwear, and clothing.

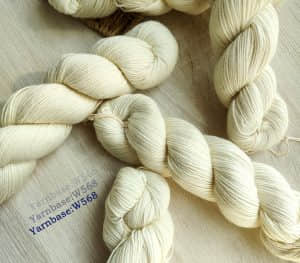

- Rich color choices: We offer a wide range of color choices to meet all kinds of design and creative needs. Whether it’s vibrant bright hues or soft, neutral tones, you’ll find the perfect color match in our aran yarn W417 range.

- Easy to knit: Aran Yarn W417 has a moderate amount of yarn, making it very easy to knit. Whether you’re a professional textile worker or a hand knitting enthusiast, you’ll find that our fleece threads are easy to handle and can easily bring your creative ideas to life.

- The strength and productivity of Loyal Yarns:

- Quality assurance: We insist on using the highest quality raw materials and adopt strict production processes and quality control measures to ensure the consistency and superiority of our products. Our aran yarn W417 undergoes strict quality inspection to meet the highest quality standards.

- Production capacity: We have advanced production facilities and technology to meet the needs of large-scale orders. Our production lines are optimized and automated to ensure efficient production speeds and timely delivery.

- Innovative R&D: Our R&D team is committed to continuously innovating and improving products to meet the changing needs of the market. We work with our customers to understand their needs and develop products according to market trends to provide our customers with the latest textile solutions.

- Sustainability: As a responsible company, we focus on sustainability. We use environmentally friendly production methods and seek to use renewable materials and energy. We are committed to reducing our impact on the environment and adhering to social and environmental standards throughout our supply chain.

If you have any questions or need further information about our aran yarn W417 or other products, please don’t hesitate to contact us. Thank you for choosing Loyal Yarns as your textile partner!

Production process:

- Choosing high quality raw materials: The first step in producing aran yarn W417 is to select high quality raw materials. Usually, 100% super-washed merino is used as the raw material for the fiber, which is popular for its softness and durability.

- Dyeing: The original merino fiber may need to be dyed to achieve the desired color effect. Dyeing can be performed before or after fiber processing, depending on production process and demand.

- Coarse spinning: Dye-treated merino fibers enter the spinning stage. In this stage, the fibers are combed and stretched to form a continuous fiber line. These fiber threads are twisted finely to form a thick spun yarn.

- Wire Finishing: Coarse-spun wire is further processed to remove irregularities and impurities between fibers. This process usually involves straightening, shearing, and rearranging the fibres to make them more uniform and consistent.

- Fine-branch spinning: After finishing the wire, enter the fine spinning stage. At this stage, the coarse-spun wire is further processed and stretched to form a finer and more uniform fiber thread. This allows the yarn spindles of Aran Yarn W417 to meet the required specifications.

- Finished product finishing and inspection: After fine spinning, aran yarn W417 will perform finishing and inspection of the finished product. At this stage, the wire is cut, sorted, and packed to ensure quality and consistency. The products go through strict quality checks to ensure that they are free from defects and defects.

- Packaging and shipping: Finally, the finished product inspected aran yarn W417 will be packaged and prepared for shipment. Packaging is usually carried out according to customer requirements and can be in small rolls, large rolls, or other forms. The products will be packed properly to ensure protection during transportation.