Introduction

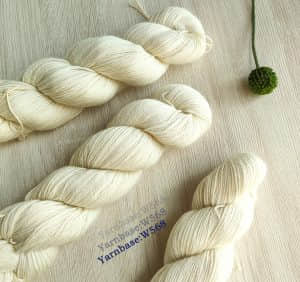

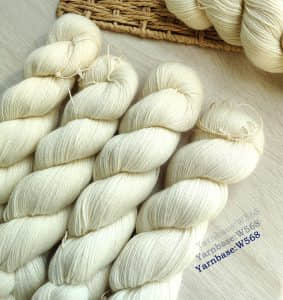

In the intricate landscape of textile manufacturing, the selection of fibers is a meticulous process that undyed yarn manufacturers undertake to craft a final product that meets stringent quality standards. This exploration delves into the types of fibers commonly employed by untinted yarn producers and elucidates how these choices intricately shape the characteristics of the final yarn product.

I. Natural Fibers:

- Cotton:

Undoubtedly a cornerstone in undyed yarn production, cotton stands out for its inherent softness, breathability, and exceptional absorbency. Undyed cotton yarns, retaining the natural color of the cotton plant, emerge as a versatile and eco-friendly option. The matte finish of cotton, coupled with its dye-retaining capability, positions it as a favored choice for undyed yarn manufacturers striving for a palette rooted in earthy, natural tones.

- Linen:

Derived from the flax plant, linen introduces a unique texture and subtle sheen to undyed yarns. Undyed linen yarns often showcase a spectrum of neutral tones, enhancing the organic and rustic appeal of the final product. The strength and durability inherent in linen fibers contribute to undyed yarns characterized by longevity, making them well-suited for various applications.

- Hemp:

In the pursuit of sustainability, undyed yarn manufacturers are increasingly turning to hemp fibers. Derived from the hemp plant, these fibers impart a natural luster to undyed yarns, presenting earthy hues that align seamlessly with the environmentally conscious ethos of undyed yarn production. The durability and eco-friendly nature of hemp make it a compelling choice for manufacturers seeking to make a positive impact.

II. Animal Fibers:

- Wool:

A perennial favorite, wool, sourced from sheep and other animals, remains a classic and reliable choice for undyed yarns. The natural shades of undyed wool yarns span from creamy whites to deep browns and grays. The versatility of wool ensures that undyed yarns offer warmth, softness, and moisture-wicking properties, making them ideal for a range of applications. The diverse breeds of sheep globally contribute to a rich and nuanced spectrum of natural colors evident in undyed wool yarns.

- Alpaca:

Renowned for their luxurious softness and hypoallergenic qualities, alpaca fibers have found a significant place in undyed yarn manufacturing. The natural colors of alpaca fibers, ranging from ivory to rich browns, contribute to undyed yarns that boast a plush and elegant appearance. Undyed alpaca yarns, thus, strike a delicate balance between comfort and sophistication.

- Cashmere:

Derived from the cashmere goat, cashmere fibers are synonymous with opulent softness and exceptional insulating properties. Undyed cashmere yarns retain the natural hues of the cashmere goat, resulting in undeniably luxurious and subtly colored yarns. The exquisite nature of cashmere makes it a sought-after choice for undyed yarn manufacturers aiming to offer premium, high-quality products.

III. Blends and Exotic Fibers:

- Bamboo:

Adding a touch of innovation, undyed yarn manufacturers often explore blends that incorporate bamboo fibers. Derived from the bamboo plant, these fibers contribute to undyed yarns with a silky-smooth texture, subtle sheen, and excellent draping properties. Bamboo blends enrich the diversity of undyed yarn options, providing a blend of modernity and versatility.

- Soy Silk:

An exotic addition to the undyed yarn repertoire, soy silk, produced from soybean proteins, introduces a natural sheen and enhanced drape to the yarn. Blending soy silk with other fibers in undyed yarn manufacturing allows for the creation of sustainable and innovative yarns. This eco-friendly option aligns with the evolving preferences of undyed yarn manufacturers and consumers alike.

IV. Impact on the Final Product:

- Color Palette:

The choice of fibers is a masterstroke that undyed yarn manufacturers wield to paint a unique color palette. Natural fibers like cotton and linen contribute to earthy tones, while animal fibers like wool and alpaca offer a spectrum from whites and grays to browns. Exotic fibers, when artfully blended, introduce distinctive hues, expanding the available color options and allowing manufacturers to cater to a broad and diverse market.

- Texture and Feel:

Each fiber variety brings forth a distinct texture and tactile experience to undyed yarns. Cotton, with its smooth and crisp feel, contrasts with the subtle roughness imparted by linen. Alpaca, on the other hand, introduces a luxurious softness that elevates the tactile experience. Undyed yarn manufacturers leverage the unique characteristics of different fibers to create textures tailored for various applications, ranging from delicate garments to robust home textiles.

- Durability and Performance:

In the undyed yarn manufacturing realm, the inherent properties of fibers play a pivotal role in determining the durability and performance of the final product. Wool, known for its resilience, imparts durability to undyed yarns, making them suitable for crafting warm and enduring clothing items. Hemp, recognized for its strength, reinforces undyed yarns intended for rugged use, providing a sustainable option for durable textiles. Strategic blending of fibers allows manufacturers to fine-tune undyed yarns, balancing strength, softness, and longevity to meet the diverse needs of consumers.

- Sustainability:

Sustainability is a cornerstone of undyed yarn manufacturing, and the choice of fibers significantly contributes to this commitment. Opting for sustainable fibers such as organic cotton, hemp, and bamboo aligns with the eco-friendly aspirations of manufacturers. Beyond the environmental benefits, the durability of certain fibers adds to the sustainability quotient of undyed yarns, promoting extended use and minimizing waste.

- Versatility:

The versatility of undyed yarns is a testament to the diverse array of fibers available to manufacturers. Tailoring undyed yarns to suit specific applications is made possible by the wide range of fibers, each offering unique properties. Whether it’s creating lightweight summer garments with cotton or crafting cozy winter accessories with wool, undyed yarn manufacturers can customize their offerings to meet the ever-evolving demands of the market.

V. Innovations and Trends:

- Recycled Fibers:

A notable trend in undyed yarn manufacturing is the incorporation of recycled fibers. Undyed yarn manufacturers increasingly embrace recycled materials sourced from post-consumer or post-industrial waste. This eco-conscious approach contributes to a circular economy by reducing waste and lessening the environmental impact associated with yarn production. Recycled cotton and wool, among other materials, provide untinted yarn producers with sustainable alternatives without compromising on quality.

- Regenerative Agriculture Fibers:

A paradigm shift in sustainable practices within undyed yarn manufacturing involves fibers produced through regenerative agriculture. This holistic approach emphasizes soil health, biodiversity, and carbon sequestration. Fibers sourced from regeneratively managed farms align with the growing environmental consciousness in the industry. Undyed yarns crafted from these fibers not only exhibit high quality but also carry the narrative of responsible and regenerative agricultural practices.

- Traceability and Transparency:

In an era where consumers are increasingly concerned about the origins of the products they purchase, undyed yarn manufacturers are responding with greater traceability and transparency in their supply chains. Providing detailed information about the source of fibers and the sustainability practices employed during manufacturing adds significant value to undyed yarns. Consumers, armed with this knowledge, can make informed choices aligned with their ethical and environmental values.

VI. Artisanal and Small-Batch Production:

- Handspun and Hand-dyed Fibers:

In a delightful resurgence, artisanal and small-batch undyed yarn production is gaining prominence. Handspun undyed yarns, in particular, showcase the individual character of each fiber, offering a unique and personalized touch to the final product. Additionally, hand-dyed undyed yarns provide a canvas for artisans to experiment with natural dyes, resulting in one-of-a-kind color variations. This artisanal approach not only celebrates craftsmanship but also appeals to consumers seeking distinctive and bespoke yarn options.

- Local Fiber Sourcing:

Undyed yarn manufacturers are increasingly placing emphasis on local and regional fiber sourcing. This strategic shift not only supports local farmers and economies but also aligns with sustainability goals by reducing the carbon footprint associated with transportation. Local fibers often possess unique qualities tied to specific climates and breeds, introducing an element of distinctiveness to undyed yarns. This localization trend enhances the storytelling aspect of undyed yarns, connecting consumers with the rich tapestry of local fiber traditions.

VII. Consumer Education:

- Understanding Fiber Characteristics:

Consumer education about the inherent characteristics of different fibers is becoming integral to the undyed yarn market. Undyed yarn manufacturers play a pivotal role in providing comprehensive information about the properties of each fiber type. This educational initiative empowers consumers to make informed choices based on their preferences for color, texture, and performance. By demystifying the world of fibers, manufacturers bridge the knowledge gap and cultivate a discerning consumer base.

- DIY and Sustainable Living Trends:

Undyed yarns have seamlessly integrated into the burgeoning do-it-yourself (DIY) and sustainable living movements. The rise of individuals engaging in crafting activities and the increasing preference for sustainable alternatives have positioned undyed yarns as a natural choice for conscious consumers. The natural aesthetics and eco-friendly attributes of undyed yarns align perfectly with the ethos of those seeking to create consciously and sustainably. As a result, undyed yarn manufacturers find themselves at the intersection of two influential consumer trends, driving the demand for their products.

VIII. Challenges and Opportunities:

- Supply Chain Resilience:

Ensuring a resilient and transparent supply chain poses a notable challenge for undyed yarn manufacturers. However, within this challenge lies a significant opportunity for collaboration. By forging strong partnerships with farmers, mills, and artisans, manufacturers can contribute to the creation of a robust and sustainable ecosystem. This collaborative approach not only mitigates challenges but also fosters innovation, efficiency, and shared responsibility throughout the undyed yarn supply chain.

- Innovations in Blending Techniques:

Continued research into blending techniques presents undyed yarn manufacturers with exciting opportunities to create novel combinations of fibers. Innovations in blending contribute to the development of unique undyed yarns with enhanced performance and visual appeal. Manufacturers exploring advanced blending methodologies position themselves at the forefront of the undyed yarn market, offering products that cater to evolving consumer preferences and industry standards.

Conclusion:

In the intricate craft of undyed yarn manufacturing, the selection of fibers is a nuanced decision that reverberates throughout the entire supply chain. The diverse range of natural, animal, and exotic fibers, coupled with strategic blending techniques, provides undyed yarn manufacturers with a rich tapestry of options. As the demand for sustainable and natural products continues to rise, undyed yarns crafted from thoughtfully chosen fibers stand as a testament to the harmonious balance between tradition, innovation, and environmental consciousness in the textile industry. The evolving landscape of undyed yarns reflects not only a commitment to quality and sustainability but also an embrace of artisanal craftsmanship and consumer empowerment.